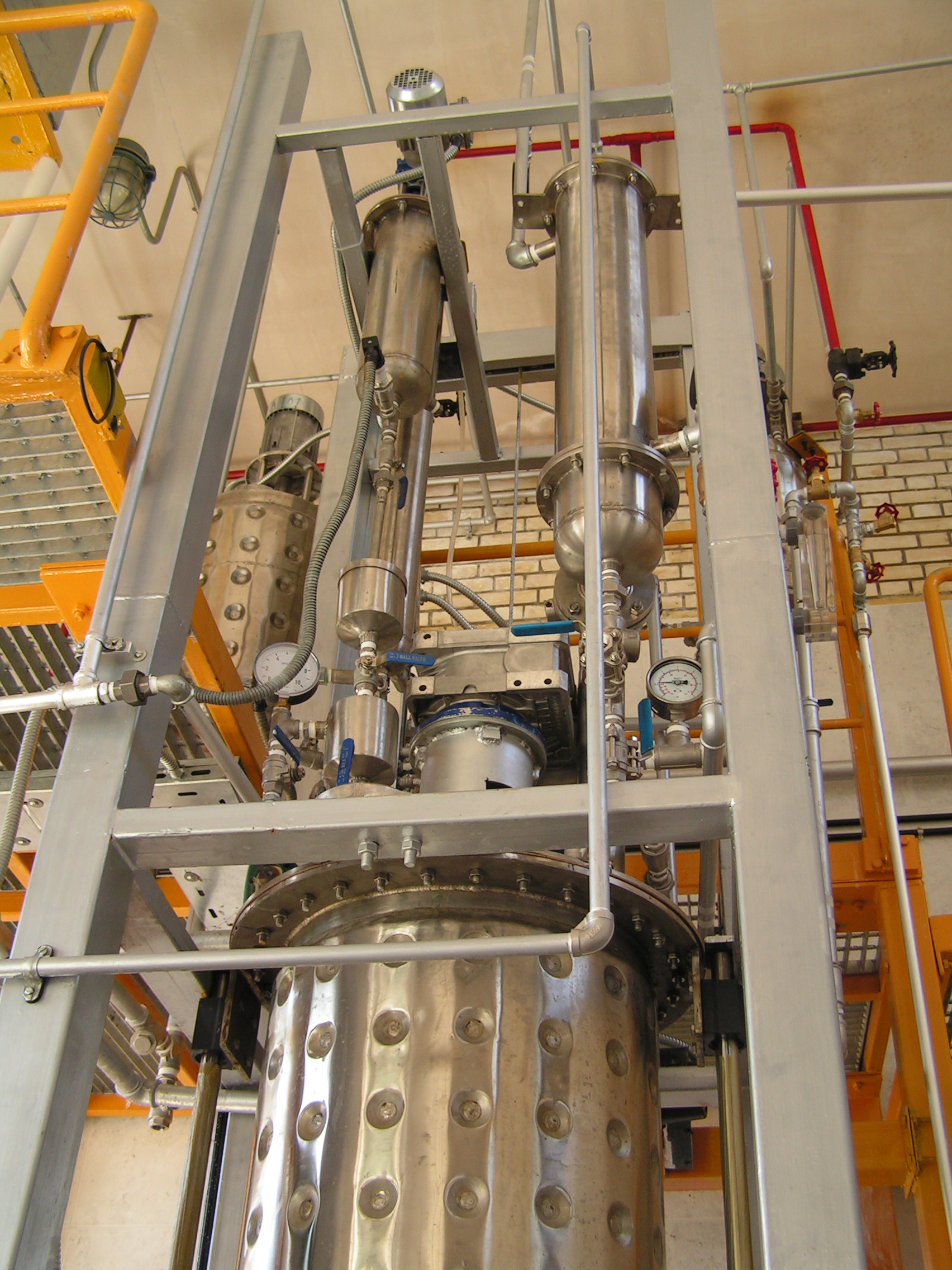

Sazaco Company is highly experienced in the advanced polymer technology and developing products and processes for the water based emulsion polymers. By designing the polymerization models and incorporating our industry expertise and experience in the emulsion polymerization reactors, we are able to design the most effective processes and operations to eliminate the heat generated by the polymerization to guarantee a safe reactor's operation and also to maintain the high quality product.

Our technology provides license with flexible process. All process designs incorporate the company's most recent commercial technology with a focus on reducing the operating cost and enhancing the reliability.

Sazaco is committed to ensuring license access to new development through continued research and development.

1- Aqueous copolymer emulsion based on colloid stabilized (Vinyl acetate & Veova)

2- Emulsion copolymer from vinyl acetate & acrylic ester & Veova

3- Non – plasticized aqueous copolymer emulsion of acrylic acid ester and styrene

4- Aqueous copolymer emulsion of acrylic acid ester and vinyl acetate

5- Non – plasticized aqueous copolymer emulsion of acrylic acid ester and methacrylic acid

6- VAC Homopolymers (Vinyl acetate monomers)

7- Plasticizer-free Aqueous copolymer emulsion of acrylic acid ester and Meth acrylic acid and Styrene

8- Self-cross linking acrylate-based copolymer dispersion

9- Aqueous copolymer emulsion of VERSATIC acid –VINYL ester and vinyl acetate

10- Non – plasticized aqueous copolymer emulsion of acrylic acid ester and vinyl acetate

Emulsion polymerization with the following capacities :

1- 10 tones per batch

2- 8 tones per batch

3- 4 tones per batch

For production of :

Homopolymers : polyvinyl acetate

Copolymers : vinylacetate-butyl acrylate